In 2020, Damen signed a contract with Blue Amigo for the delivery of nine passenger vessels. The ferries will operate services between Rotterdam and the Drecht cities in the Netherlands in a service known as the Waterbus.

Damen identified that six of the vessels – hybrid carbon fibre water buses that will operate fast, inter-city routes – would require a thruster that had not been seen before. What was needed was a fully azimuthing, 360-degree thruster that would make docking easy and propulsion fast.

“It’s actually the kind of thruster you would expect to see on a pleasure craft,” says Damen design and proposal engineer Ferries Jan van Ooijen. “On a passenger vessel, though, we needed something more manoeuvrable and robust.”

Damen approached the experts of Hydromaster, a company with decades of experience in the field of steerable propulsion. Renowned for their sturdy, fully-mechanical design, Hydromaster thrusters propel hundreds of ferries, ships, barges and pontoons every day – all over the world.

The two companies joined forces to develop this new thruster, as Hydromaster commercial manager Jan Terlouw explains. “We had already been working on something that would meet these requirements. A 375kW thruster, able to operate at speeds of up to and beyond 25 knots and durable enough to cover over 4,000 hours each year. But we had never built it. Once Damen signed its contract with Blue Amigo, we got the green light to go ahead.”

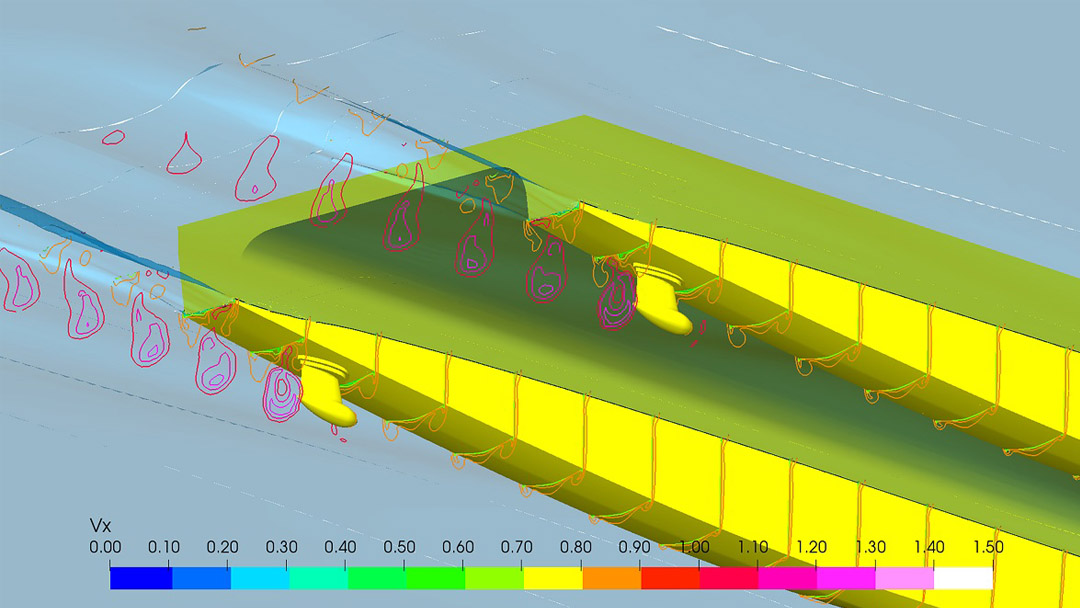

Before that, however, Hydromaster went to MARIN. The Maritime Research Institute Netherlands worked together with Hydromaster to develop the hydromechanics necessary to produce the thruster.

MARIN was able to provide the detailed calculations that would facilitate a computational fluid dynamics (CFD) study and the fine-tuning of Hydromaster’s design.

Jesse Slot project manager ships at MARIN: “It’s always a challenge to strike a balance between efficiency and vibration. Because of the high speed required in this instance, to took us some time to get where we needed to be.”

Using its extensive experience and conducting a thorough assessment of Damen’s hull design, MARIN was able to come up with the solution – a propeller of 840mm diameter with a clearance of 23% diameter from the hull -reducing vibration to a minimum and allowing for increased efficiency.

For control of the thruster, Damen has developed in-house a single joystick controller that is intuitive to use and fulfills the circle of efficiency offered by the thruster.

Jan van Ooijen: “This is a compact installation that takes the concept of standardised shipbuilding and applies it on another level. The result maximises the performance of the vessel and offers the reliability required for a ferry service. We can see a future for this type of thruster.”

Jan Terlouw agrees, “We have already started to extend this range of High Speed Azimuth thrusters with a higher power output towards the 900 kW mark. We see a good potential for this type of thruster, not only for fast ferries, but also for example on crew transfer vessels for the offshore wind sector, supporting the production of sustainable energy, and other fast craft.”